Aerial Drones in Mineral Exploration

Introduction

The Unmanned Aerial Vehicle (UAV or “drone”) industry is evolving at breakneck speed, and it is often difficult for mining companies to keep up. In fact, it has been said that a “drone year” is the equivalent of one calendar month due to the pace of change the market is experiencing. However, despite the difficulty of staying abreast of changes, drones offer incredible potential to transform the mining industry. Therefore, it is critical for mine operators, entrepreneurs, and investors to better understand this new and emerging technology.

UAVs are turning the mining sector into an emerging frontier for new technology, and in recent years have helped the industry find cheaper and safer ways to map deposit sites and explore for minerals. With the ability to monitor stockpiles, map exploration targets and track equipment, the potential applications for drones in the mining industry – T are practically limitless. UAVs offer tremendous efficiency and cost advantages in every part of the mining life cycle including exploration, planning/permitting, mining operations and reclamation.

Lidar sensor mounted on Procyon 800 E UAV – Global UAV Technologies Ltd

Payload technology – the amount of weight and equipment a drone can be equipped with – is advancing rapidly also. Tasks that were hard to accomplish even a year ago are possible with the latest drone models, with some of the biggest gains being seen in the agricultural industry; however, the mining and mineral exploration industry is not far behind. It is amazing that the changes drones are bringing to mining right now are taking place in an industry that dismissed this technology as a mere fad just a few years ago. To a great extent, this usage growth has been fueled by the enthusiasm with which investors have supported drone start-up companies.

One of the most significant benefits of using UAVs is the cost. Far cheaper than traditional manned aviation platforms, drones are reshaping the way that all of these industries survey new areas, providing better results for a fraction of the price. The adoption of drones for industrial purposes is rising quickly and can save businesses significant amounts of money while producing unique, valuable and task critical outcomes. For example, drones can map an area in high resolution in less than a day, usually a couple of hours. The cameras on today’s drones have also benefited from recent advancements in small, high-resolution sensors.

Additionally, miniaturization of other components such as GPS and computer boards has contributed to the modern UAV’s utility in the industry by making the UAVs lighter and therefore able to fly for longer times and cover more ground per flight. Due to the unmanned nature of a drone it can fly close to the ground, which allows unparalleled image resolution. Conversely, traditional manned aerial survey aircraft require cameras with extremely high resolution because they fly at elevations of 2000-5000 ft above the survey area. Drones can fly at 250 ft with a lower resolution camera camera and get better data.

UAV’s in Aerial Mapping

Using UAVs, early stage mineral exploration projects can now get a rapid aerial image mosaic produced by a drone for a couple thousand dollars, where a conventional aircraft would produce an inferior product for about ten times the cost. This cost advantage allows imagery to be collected very early in the exploration process, when it can be of the most benefit, and that imagery is used to reduce the ground that an exploration team needs to cover by ground.

In addition to aerial imagery, the same drone data can be used to produce accurate topographical maps and GIS data in remote areas. Topographic mapping has traditionally been produced by ground surveyors. Previously, you would have to pay a survey crew to walk the entire property and collect GPS points to be used in a map. Today however, mapping drones can do this without the need for any ground control points at all (though for centimeter-level accuracy, a ground control point is still used). The combination of low cost aerial imagery and terrain data allow modern explorers to have a close up view of any property in 3D. Having this capability in early stage exploration aids significantly in project planning, which reduces exploration costs and expedites fieldwork.

UAV’s in Resource Modelling

Mining companies are also using UAVs and highly detailed topographic mapping techniques to estimate the size and therefore value of mineral stockpiles. UAVs are used to generate a 3D model of the stockpile to centimeter-level accuracy, and that model generates a volume for the pile. This volume is then used to determine the amount of ore or mineral product that is present. Stockpiles can be monitored in this way over time to determine changes in stockpile size – which is very useful for mineral processing operations or aggregate operations, as well as tolling mills.

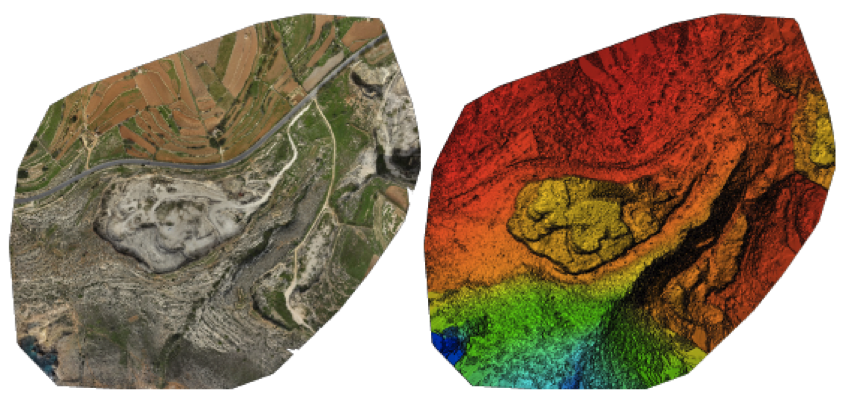

The same technology is also used to quantify the size of quarries and pits, by creating a three dimensional model and calculating the volume of the void. Similar to the value proposition with ore piles, the volume of quarries or pits can be calculated over time with repeated drone flights, allowing for verification of production volumes down to centimeter-level accuracy. In the figure below, the software package Pix4D was used to create the orthomosaic and Digital Surface Model (DSM) from data captured with an eBee RTK UAV with SODA camera.

Orthomosaic (Left) and Digital Surface Model of a Quarry in Malta flown with an eBee UAV and processed using Pix4D for the Maltese Government to calculate the quarry’s volume.

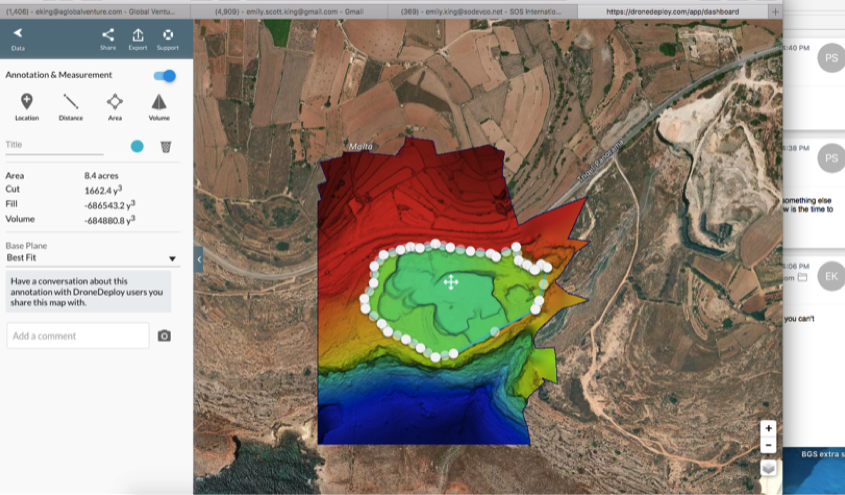

After using the software to process the orthomosaic into a three dimensional model, the software can then be used to calculate the volume and area of the quarry or any other topographic feature. Software is oftentimes sold with a UAV so that the systems are integrated, but companies like Drone Deploy are also available, where data is uploaded to a remote server and then processed and sent back to the user as a finished product. In the image below, DroneDeploy was used to calculate the volume and area of the quarry.

Screenshot using DroneDeploy to process Malta Quarry data to determine volume and area of quarry.

UAV’s in Geophysical Surveys

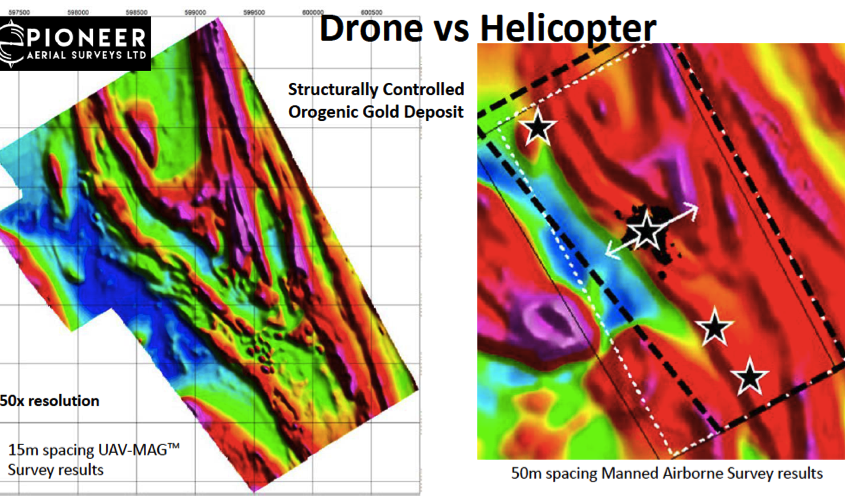

At the cutting edge of UAVs in the mining industry is the use of drones to capture geophysical data. A leader in this field is Pioneer Aerial Surveys, a Canadian company owned by Global UAV Technologies Ltd (CSE:UAV) leading the mining and exploration industry in UAV based remote sensing and commercial grade drone helicopters such as the Procyon 800E.

Pioneer developed the first commercially available UAV supported aeromagnetic sensor systemin 2014, and grew to become the largest drone-based geophysics survey provider to the mining industry worldwide today. Their technology and services have been used by companies like DeBeers Diamonds, Anglo American, Rio Tinto, TECK and SSR Mining on four continents and in more than 10 countries.

Comparison of Magnetic Survey resolution captured with a UAV (left) compared to a helicopter (right) courtesy of Pioneer Aerial Surveys Ltd.

GEM Systems (GEM) is another player in the field, with their GEM DRONEmag™ a quantum magnetometer developed specifically for drone magnetometer surveys. With high-resolution and low noise threshold (high sensitivity), GEM’s drone magnetometer is a Ultra Light-Weight Potassium Magnetometer that can be flown using a variety of UAV platforms that GEM sells – it has been installed and successfully tested on the Monarch Fixed-Wing Gradiometer, the GEM Copter Multi-Rotor UAV and the GEM Hawk Helicopter UAV, allowing flexibility for companies to buy just the sensor or a complete package. Unlike Pioneer, who is a service provider, GEM sells the hardware for companies to fly themselves.

Conclusion

While more and more companies in mining are planning to incorporate drone-based aerial surveys into their operations, many continue to struggle with whether to bring drone operations in-house or contract with third-party drone service providers to perform aerial surveys for them. Since the idea of having in house drone operations suggests a significant investment in training and equipment, most companies have determined that it’s better to simply hire drone service providers. Similarly, many exploration-for-hire firms have integrated UAVs and associated sensor technology into their offerings, so that companies hiring out for exploration or drilling can request these services and products as a part of their larger exploration service.

Drones may not yet be in use in every single mining operation, but this technology is clearly here to stay. As long as investors and exploration geologists continue to see value in knowing more about a remote deposit faster, Drone use will become far more widespread throughout the mining industry. Additionally, more and more exploration prospects will incorporate UAV data in their promotional packages, so it will be increasingly important for investors to understand what UAVs are, how they work, and the limitations and constraints as well as benefits of using them to capture datasets.